HELIX® M45 WELD HEAD

A weld head that does it all – plus fits into tight spaces.

BUILDING UPON A GREAT PLATFORM

The HELIX® M45 is the second innovation to our HELIX M Series orbital weld heads. Like the HELIX M85 weld head, the HELIX M45 weld head is designed on the Power Wave® platform for advanced / multi-process capabilities. It embodies all of the same features, functions and ruggedness of the HELIX M85, but in a low-profile package. With a radial clearance of 4.5″ (114 mm), The HELIX M45 weld head easily allows welding in areas with physical constraints.

DESIGNED WITH THE OPERATOR IN MIND

Intuitive ergonomic design offers tool-less adjustments from a color scheme of knobs and handles. Color coding the latch and clutch handles has made mounting the weld head to a flat track or track ring almost effortless.

Comparable to the HELIX M85 weld head, the M45 weld head’s digital platform automatically calibrates the motion axes, requiring no manual intervention from an operator or technician. Our digital platform offers many advantages including simple troubleshooting, go or no-go type testing, and lightweight, cost-effective cabling. Built into the weld head’s design is the ability to make upgrades for future feature and technology enhancements, extending the life of the system and minimizing product obsolescence.

SIZED JUST RIGHT FOR THE JOB

The HELIX M45 is well equipped, incorporating a 2″ (51 mm) torch height stroke length and a 5″ (127 mm) oscillation stroke length. Extended stroke lengths are available from 5″ (127 mm) to 15″ (381 mm) for the torch height stroke and up to 24″ (610 mm) for the oscillation stroke length.

PRODUCT CONFIGURATIONS

The HELIX® M45 weld head is capable of GMAW and FCAW weld travel speeds, but has the precision and accuracy needed for GTAW, Hot Wire GTAW, and Laser operations. Repeatable welds and operations are the key in orbital welding and the APEX® / HELIX® system was engineered for exactly that. To further advance repeatability, the HELIX M45 weld head incorporates an inclinometer to allow automatic weld parameter changes based upon the torch position on the pipe.

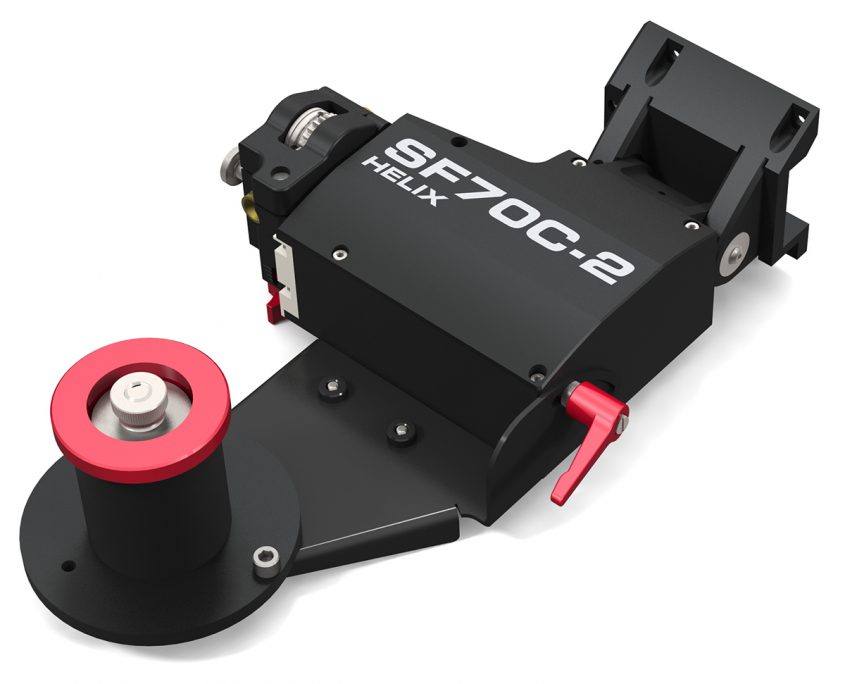

HELIX® SF70C-1 and HELIX® SF70C-2 M45 ONBOARD WIRE FEEDER

Optional HELIX M45 weld head onboard wire feeders are available for GMAW / FCAW and GTAW welding applications. These wire feeder modules and other available modules make switching between different processes and applications quick and easy. All of this is achieved while still providing rugged and reliable welding equipment that you have come to expect from the welding experts of Lincoln Electric.

The HELIX® SF70C-1 and SF70C-2 M45 onboard wire feeders offer precise and accurate wire-feeding performance, with “plug and play” capability that mounts directly to the HELIX M45 weld head. Featuring brushless DC servomotors with encoder feedback, the SF70C-1 and SF70C-2 M45 wire feeders help improve quality and consistency over a broad range of wire-feed speeds.

- Unsurpassed Power Density – High-torque output in a compact lightweight package.

- Precise Speed Control – High-resolution encoder for precise control over a wide range of speeds.

- Hassle-Free Adjustment – Toolless adjustment of drive roll tension and feeder placement.

- Environmental Resistance – Stainless steel hardware and coated PC boards for moisture and corrosion protection.

- Versatile and Flexible – Drive rolls available in a wide range of sizes for solid, cored and aluminum wire.

- Synchronized – Both single and dual setups can be synchronized with magnetic oscillation, mechanical oscillation and pulsed amps for unparalleled wire delivery right where you need it.

RAPID DIAMETER CHANGE

While maintaining the 4.5″ radial clearance the HELIX M45 can rapidly change from 8″ pipe diameter to 24″ and greater without modifying the weld head. The design allows the head to rapidly adapt without the complexity that other products require.